Shapeways is pleased to have partnered with BASF to bring you access to four Forward AM materials: Ultrasint® PP nat 01, Ultracur3D® RG 35, Ultrasint® TPU01 and HP High Reusability PP. These durable and versatile materials facilitate a high level of design complexity and accuracy, producing functional, resistant prototypes and end parts with first-rate surface quality. Common applications for these materials include automotive, industrial, aerospace and consumer goods.

Here are some details on each of these four material options, and a comparison guide to help with your material selection process.

Ultrasint® PP nat 01

Polypropylene (PP) is one of the most commonly used plastics materials printed using Selective Laser Sintering (SLS) technology. Highly flexible and durable, it has a low moisture absorption rate and is resistant to most acids and bases, which makes it a great choice for parts with water contact. Ultrasint® PP nat 01 suits a range of applications from healthcare and orthopedic products to electronic and automotive parts and allows for post-processing such as thermoforming and sealing. It is a sturdy material that is well suited to industrial parts and production.

| IDEAL APPLICATIONS: |

| Pipes and Ducts |

| Water Manifolds and Reservoirs |

| Economic and Functional Prototypes |

| Multi-Purpose Industrial Goods |

| Durable Jigs and Fixtures |

Ultracur3D® RG 35

This rigid, medium viscosity photopolymer is great for printing high-performance, functional and multi-purpose parts using Stereolithography (SLA), Digital Light Processing (DLP), or Liquid Crystal Display (LCD) machines. Parts produced with Ultracur3D® RG 35 are able to maintain extreme accuracy. It is a solid, tough material and is recommended for functional parts such as air ducts, electrical sockets and connectors.

| IDEAL APPLICATIONS: |

| Snapper |

| Air Ducts |

| Electrical Sockets |

| Thermoforming Molds |

| Connectors |

| Jigs and Fixtures |

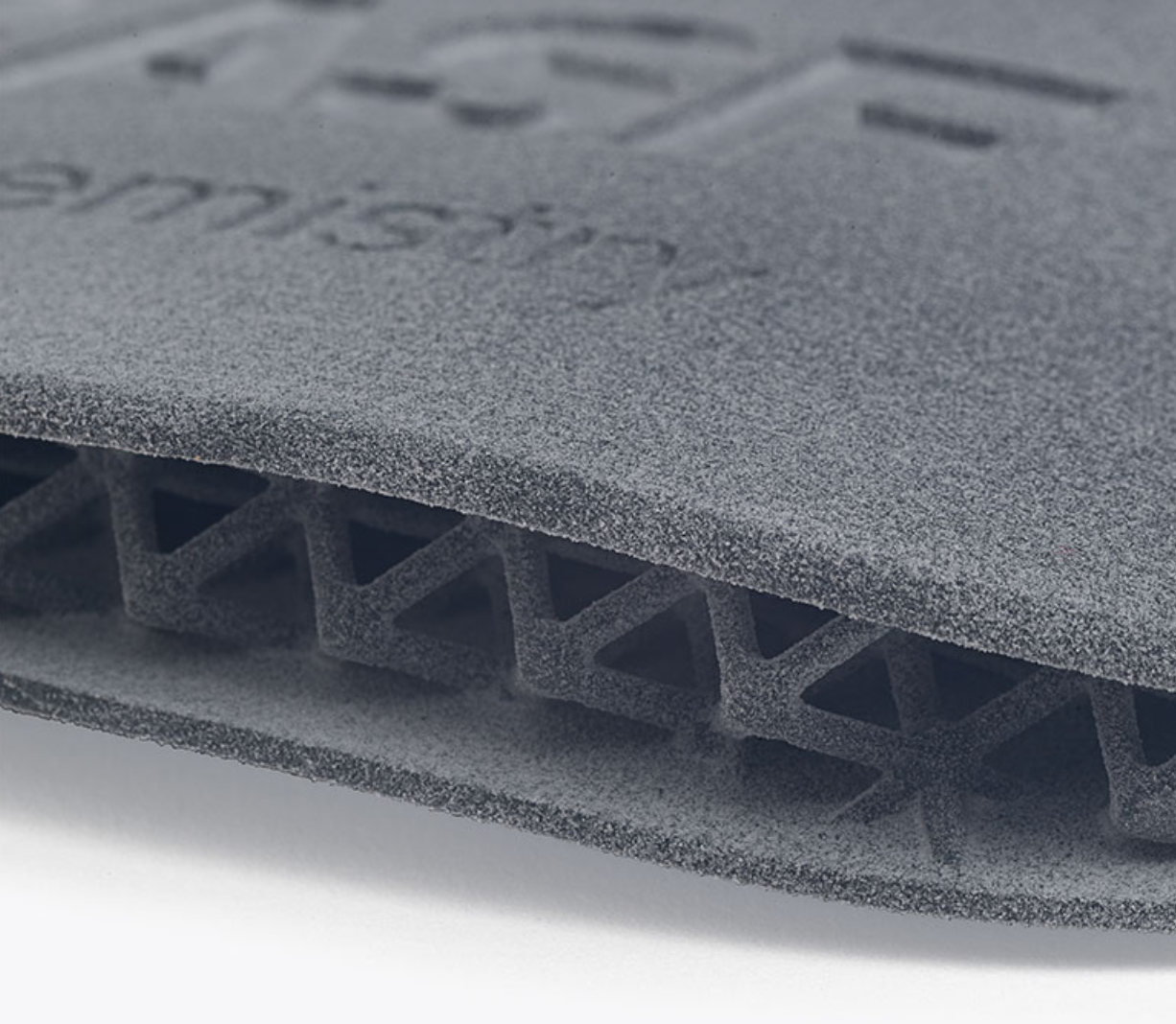

Ultrasint® TPU01

Ultrasint® TPU01 is a multi-use thermoplastic polyurethane that typically comes in white and printed using Multi Jet Fusion technology. It is a highly flexible material with excellent shock absorption, making it ideal for footwear and other elastomeric parts. It is capable of producing a high level of structural detail and intricacy and is UV and hydrolysis resistant. It has excellent surface quality, high process stability and throughput and its flexibility opens it to a myriad of uses that include sporting goods and protection as well as interior automotive components and orthopedic models.

| IDEAL APPLICATIONS: |

| Sporting Goods |

| Footwear |

| End Use Automotive Parts |

| Lattice Structures for Custom Performance |

HP High Reusability PP

HP 3D HR PP is a highly versatile and durable polypropylene material. It is chemically resistant and has a low water absorption rate, which makes it a great choice for piping, fluid systems and containers. It is the HP 3D material that costs the least and is very easy to process, which increases productivity and reduces waste. Because it is both cost-effective and functional, the material is well suited for prototypes as well as end parts. It is a highly flexible material that is weldable to other PP parts, expanding its range of applications from the automotive industry to the consumer goods sector.

| IDEAL APPLICATIONS: |

| Piping and Fluid Systems |

| Containers |

| Interior and Exterior Automotive Parts |

Material Properties: Ultrasint® PP nat 01, Ultracur3D® RG 35, Ultrasint® TPU01 and HP High Reusability PP

Take a side-by-side look at each of these materials’ properties below:

| Tensile Strength X | Tensile Strength Z | Heat Deflection Temp (0.45 MPa) | Tensile Modulus X | Tensile Modulus Z | Elongation at Break X | Elongation at Break Z | |

| Ultrasint® PP nat 01 | 28 MPa | 28 MPa | 102 °C | 1400 MPa | 1400 MPa | 30 % | 10 % |

| Ultracur3D® RG 35 | 49 MPa | 49 MPa | 84 °C | 1990 MPa | 1990 MPa | 4 % | |

| Ultrasint® TPU01 | 9 MPa | 7 MPa | 75 MPa | 85 MPa | 220 % | 120 % | |

| HP High Reusability PP | 30 MPa | 30 MPa | 100 °C | 1600 MPa | 1600 MPa | 20 % | 18 % |

Ready to give these materials a try? Upload your model here to get an instant quote.