Heat resistance is a highly sought after feature in 3D printing, mainly for parts that will be subjected to potential extremes and also for those built to last. These desirable 3D printing materials often have other required properties too, such as durability, stiffness, and the ability to support complex geometries that may not be possible through other manufacturing methods.

Understanding what thresholds in heat resistance actually mean in relation to 3D printing is beneficial, as well as to the process of manufacturing overall; for instance, if an aerospace company is engineering parts that must survive on another planet like Mars in the future, they seek thermoplastics and metals that can withstand extreme elements. The same goes for automotive applications where engineers must ensure that parts for both interiors and exteriors do not corrode or deform in the beating sun–or winter cold.

More importantly, ‘heat-resistant’ implies that materials and 3D printed products can withstand a high or even extreme temperature without being burned or melted–but they are not impervious to fire–and each has its documented limit in terms of temperature.

3D Printing Applications Requiring Heat Resistance

A high deflection point demonstrates heat resistance up until the point that a part begins to deform. This quality is desirable for the best heat resistant 3D printing material in the following industrial applications:

- Aerospace – Stability and heat resistance are typically required in aerospace applications, especially for parts related to rockets, pumps, nozzle materials, heat shields, and other flight-ready parts.

- Automotive – This is one of the most common applications requiring heat resistance, as virtually all parts require protection. 3D printed parts, whether used as prototypes during product development or as functional components under the hood, must be able to withstand the heat–as well as corrosion–to avoid distortion or breakdown of materials. Parts may include wheel assemblies, grills, and gaskets. Interior components include gear-shifting devices, interior amenities, housings for electronic parts, and handles.

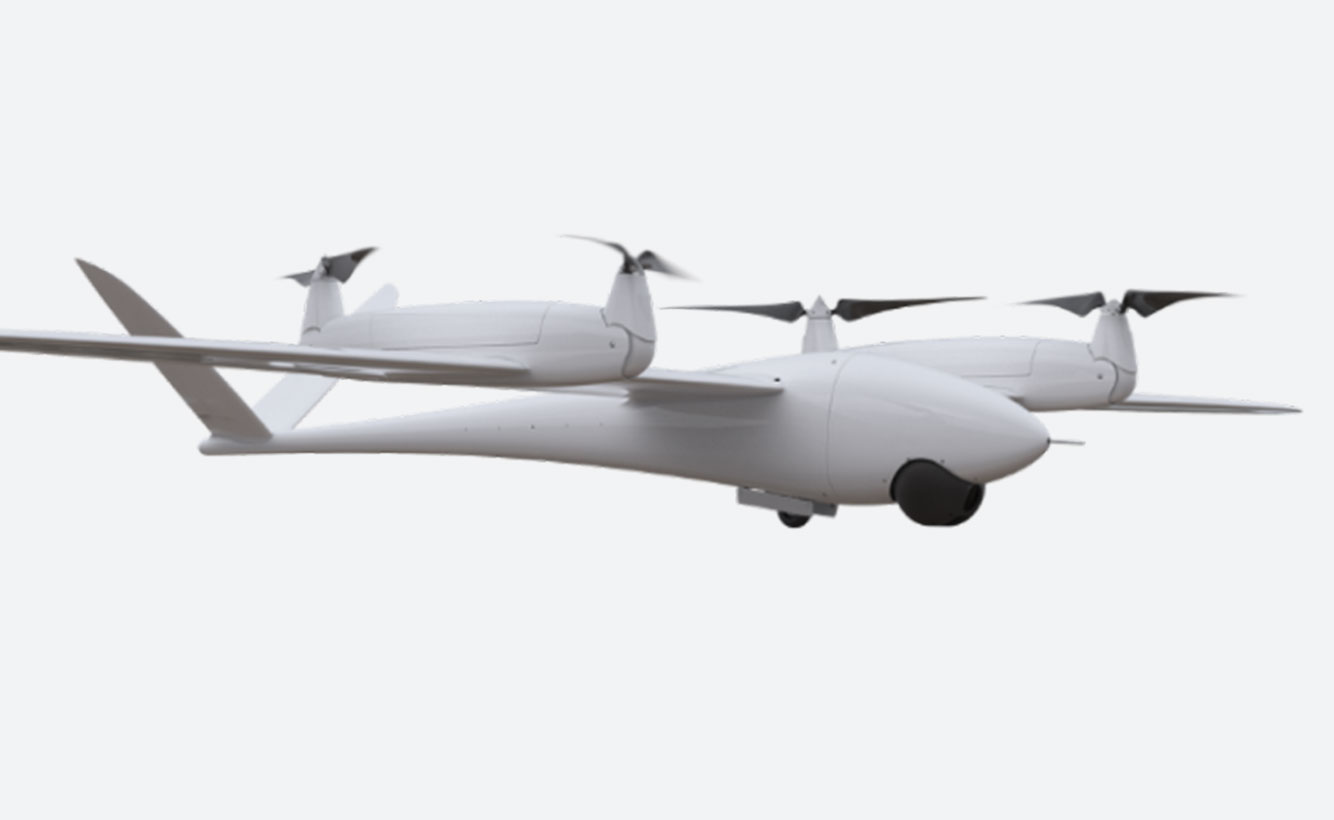

- Drones – These aerial devices may be tasked to fly in weather conditions that include extreme temperatures, as well as over regions stricken by wildfire. With the ability to fly over heavily forested areas that may be experiencing uncontrolled fire, drones are expected to take the heat.

- Consumer products – 3D printed parts that may be used or stored outside are particularly vulnerable to weather, including furniture components, sports and recreational equipment, and more.

- Electronics – Antennas, and cases and housings for electronic circuits and other devices must also be manufactured appropriately for heat and extreme temperature conditions.

Advanced 3D Printing Materials and Technology

Some Shapeways customers now use the same advanced 3D printing materials for prototypes and functional products, enjoying continuity throughout the entire product development, manufacturing, and re-ordering process. Using the same materials often means placing a priority on materials like Nylon 11 [PA11(SLS)], seeking the best heat resistant 3D printing materials as well as impact-resistance and corrosion-resistance too.

Shapeways offers the following in heat resistant 3D printing materials:

Nylon 6 Mineral Filled (PA6MF)

Especially suited for 3D printing automotive applications–including 3D printed auto parts often in close proximity to the engine–PA6MF is 3D printed with Selective Laser Sintering (SLS) and offers great heat resistance, strength, and stiffness. Filled with mineral reinforcements, this 3D printing material is imbued with enhanced impact resistance, featuring isotropic rigidity and properties similar to injection molded parts but without causing the added time and expense. Designers and engineers choose PA6MF for both structural parts and high-performing, functional prototypes too.

The heat deflection temperature for PA6MF is 209°C. Find out more about this industrial 3D printing material and accompanying design guidelines here.

Nylon 11 [PA11(SLS)]

Featuring strength, durability, and heat resistance, Nylon 11 [PA11 (SLS) parts are 3D printed with Selective Laser Sintering (SLS)–and built to last over the long term. Often targeted for use in automotive, aerospace, and drone applications, this material is well-known for its ability to hold up to rigorous conditions like heat and weather. Excellent impact resistance makes it suitable for parts like protection equipment for sports too. Nylon 11 [PA11(SLS) is also resistant to a wide range of chemicals.

The heat deflection temperature for Nylon 11 [PA11(SLS)] is 180°C. Find out more about this versatile 3D printing material and accompanying design guidelines here.

3D printed with Multi Jet Fusion, MJF Plastic PA12 is a heat-resistant thermoplastic meant to support complex geometries and detailed, dimensionally accurate parts with finely tuned mechanical properties. This material also offers great strength, durability, and stiffness. Suited for a wide range of applications, MJF Plastic PA12 is 3D printed for durable end-use goods to include high-performance industrial parts, smaller components like mounts and brackets, consumer goods and more.

The heat deflection temperature for MJF Plastic PA12 is 95°C. Find out more about this popular 3D printing material and accompanying design guidelines here.

MJF PA12 Glass Beads (MJF PA12GB)

Also 3D printed with Multi Jet Fusion, MJF PA12GB is an excellent choice for applications like large, flat parts that may be prone to warping with other materials. This material is suitable for high-performing 3D printed parts that require high strength and dimensional accuracy. Engineers 3D print with MJF PA12GB for applications like robotics, drones, medical, housing and cases, and tooling.

The heat deflection temperature for MJF PA12GB is 114°C. Find out more about this popular 3D printing material and accompanying design guidelines here.

Relying on Selective Laser Melting (SLM) technology, Aluminum alloy AlSi10Mg provides good heat resistance, as well as offering a lightweight material that is also strong, durable, and accurate. This Aluminum 3D printing material also provides excellent corrosion resistance, and high electrical and thermal conductivity. 3D printed Aluminum can be machined, milled, and tapped, and is ideal for outdoor applications.

The heat deflection temperature for this Aluminum 3D printing material is 570° C. Explore the accompanying design guidelines here.

This extremely heat-resistant metal is 3D printed with Binder Jetting technology. Also offering excellence in corrosion resistance and tensile strength, this metal 3D printing material is a single alloy, 100% Stainless Steel. Shapeways customers rely on Stainless Steel 316L for 3D printing mechanical machinery and parts like heat exchanges, fasteners and brackets, and surgical tooling for medical applications.

The heat deflection temperature for this metal 3D printing material is 1375-1400° C. Find out more about this popular metal 3D printing material and accompanying design guidelines here.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.