HP’s Multi-Jet Fusion printer is now available to everyone! Starting today, anyone can order their own models in HP Nylon Plastic, available in both Raw Gray and Black. We’re excited about the the material’s progress in strength, stiffness, shock absorption, and finish. Learn more about the story behind it below.

DEVELOPMENT PROCESS

With every new material and technology we offer, we work closely with our community and technology partners to improve and develop it. Our testing and evaluation of this new technology started back in 2016 when Shapeways partnered with HP and received the very first prototype printer in the field. Our 3D printing engineers spent months user-testing this machine and providing expert feedback to the HP team to help drive development of this revolutionary technology.

The HP Jet Fusion Printer in action

Once we received the first production machines, we invited community members to our Eindhoven factory to get feedback on the material in their designs and to get an in-depth look at our process.

A designer from our community tests out HP Nylon Plastic

In April, we opened Early Access to HP’s Multi-Jet Fusion technology. Since then, together, we have been rigorously testing the capabilities with thousands of different applications and geometries, thanks to our diverse community’s endlessly varied, one-of-a-kind products. This has enabled us to have an extraordinary and unique understanding of the material and process.

DETAILS

You have helped us prove that prints developed with HP have excellent mechanical properties, a smooth surface, and a more finished look. Both the quality and strength of HP have not yet been matched by other materials, showing the ingenuity of this new technology. Over the course of developing the material, your insights have also helped us drop our lead time to 6 days.

Because of the increased strength, durability, and smoothness, this new material will be introduced at a higher price than our Strong & Flexible family of plastics.

Along with our community, we hope that in the future the HP printers will help us to lower costs for our users. It is HP’s mission to create the fastest and least expensive nylon printer on the market, and we are grateful to continue working with them to help make this happen.

As roll out HP to all of our makers, we are renaming the material from HP Strong & Flexible to HP Nylon Plastic to distinguish it from our Strong & Flexible family. We have also made updates to the design guidelines, pricing, and lead time.

Testing bracelets printed in HP Nylon Plastic

USES

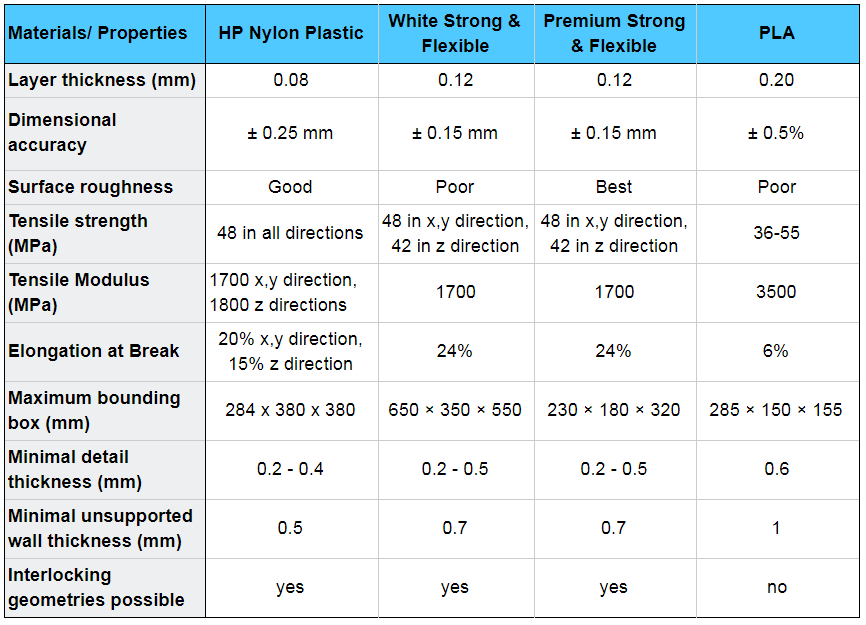

Due to its superior mechanical properties, we recommend HP Nylon Plastic for functional products that require high strength, stiffness, elongation, and isotropic properties, such as RC cars, mechanical, and casing parts. If you’re not sure if HP Nylon Plastic is the right material for your project, see the comparison chart of functional plastics below.

WHAT’S NEXT

In the near future, we plan to make HP Nylon Plastic available for Shop Owners to offer as well. But first, we’ll need your feedback on the material. What has worked for your own models? What are things to watch out for, or unexpected uses for the material? With your help, we’ll soon be able to offer HP Nylon Plastic to all marketplace shoppers.

We’re grateful for your feedback and ingenuity as we continue to develop new technologies together. We can’t wait to see what you make with HP Nylon Plastic! Upload your design here.

- Hangitall Micro by DESIGNNETA

- Jürgen Kleimeier’s Model Plane

- iPhone 7 Plus Grid CaseCase Click by CASECASECLICK

So how do you justify the 100% price increase to this material from Beta to Maker only material? It was a great material and again I was about to order a bunch of parts as stock but your unwarranted 100% price increases on materials has put a stop to that. I guess with 3Dprinting getting more mature and more reliable it has resulted in more business which makes you get greedy so you start jacking up your prices to afford another yacht and Bugatti.

I have just seen the 100% increase in price and its very disappointing, this technology is supposed to be 10x faster than SLS which obviously means more production in less time = more profit which in turn allows for lower prices.

Hi Sublime! I’m Shapeways’ Content Lead. We hear you and we are absolutely on your side here. Along with the community, we hope that the cost will come down to become a more affordable option for everyone. Thank you for raising these concerns. The beta testing price was issued below cost, so it may feel like a shock. However, the quality of the material is fantastic and this is the only possible price point at this time.

Hi UninterRC, I’m Shapeways’ Manager of Community. We understand your concerns here! We are working closely with HP to get closer to the speed and price goals that were originally promised. We thought it best to open this technology as soon as possible to the community so you can participate in the technology’s development.

HP’s material data sheet boasts about fine detail and high dimensional accuracy, yet your table says +/- 0.25 compared to Strong & Flexible’s 0.15 mm. Please explain. If I’m reading the properties right, it should be slightly worse, but say, is it as suitable for functional springs, living hinges and snap-fit designs?

The section about cavities isn’t exactly reassuring. The price increase just knocked it out of consideration for the near future.

Hi Thorwil — Yes, the dimensional accuracy that we have measured is +/- 0.25 mm, which is slightly worse than Strong & Flexible. However, if you design with these tolerances in mind, you can still make snap-fit designs such as cases, etc. The technology still produces fine detail, but the dimensional accuracy will effect the overall thickness of your design. This is a consistently stronger material, so we encourage you to use it for functional applications.

I can confirm that 0.2mm is available, yet there is a problem with material shrinkage and print orientation on thicker parts:

https://www.youtube.com/watch?v=RKNd4U5drjM