Today we’re super excited to announce a massive step in a partnership that will help revolutionize the way the world looks at product design and digital manufacturing. We have installed the new HP Multi Jet Fusion 3D printer at our factory in Eindhoven, the Netherlands.

Why are we excited? Back in 2014 we learned from Hewlett Packard, a company that holds true to a long history of deep innovation, that they were working on a new 3D printer. They told us that the new machine would be built for finished manufacturing (not only prototyping), would deliver great quality, would be 10x faster than existing machines and deliver parts at greatly reduced cost. We know that better quality, lead times of 1 or 2 days and lower prices are exactly what the market needs.

That is why, in October that same year, we announced a partnership with Hewlett Packard. This collaboration will enable both Shapeways and HP to work side-by-side to take 3D printing and digital manufacturing to a new level, with the official introduction of their new HP Multi Jet Fusion 3D Printing System.

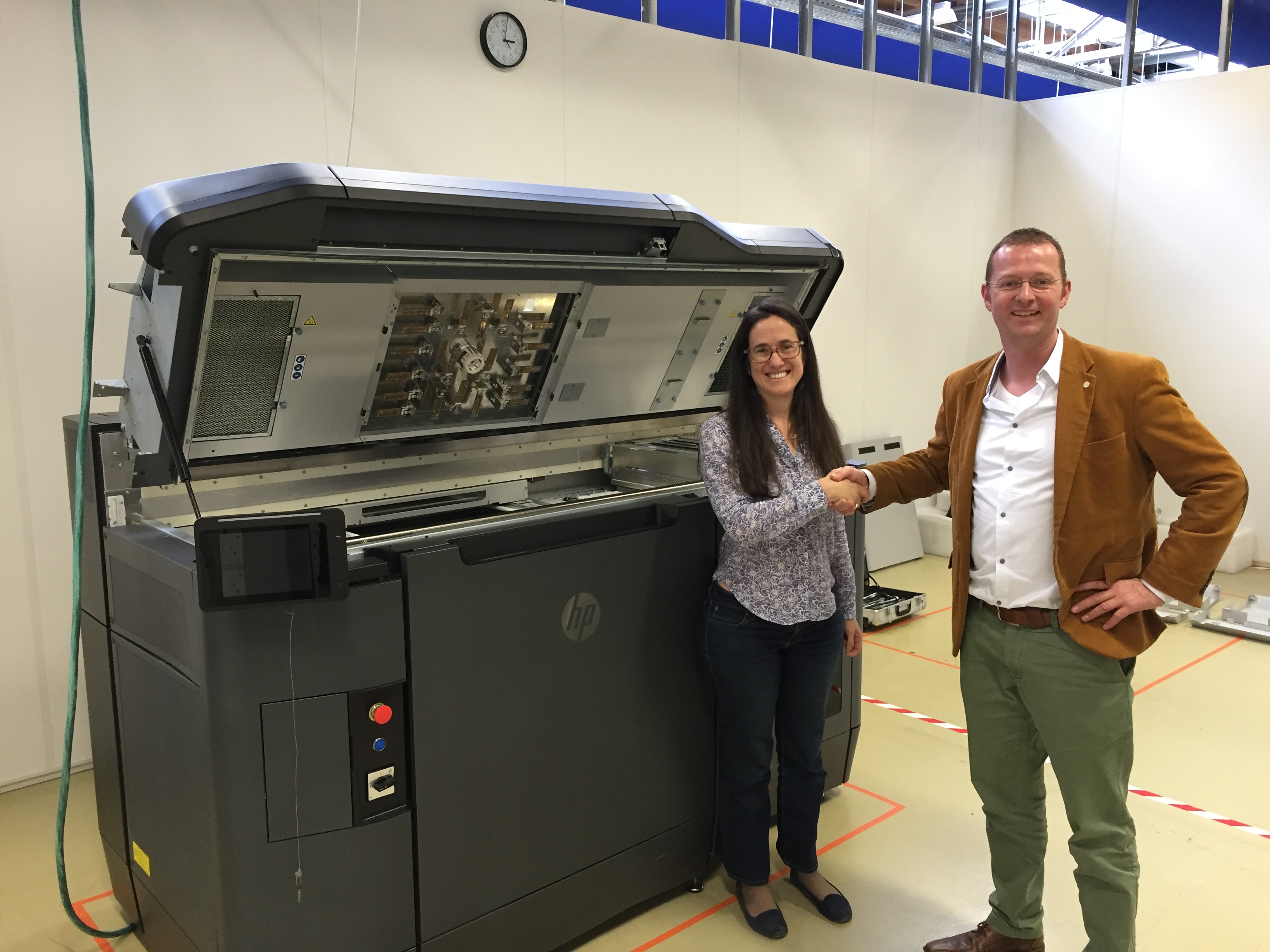

During the last year and a half, teams at both HP and Shapeways have been working together forging the next milestone, which we are celebrating today; the announcement of this new printer by HP at RAPID and it’s first installation in our Eindhoven factory.

Being the first to take delivery of a prototype on this new platform in our Eindhoven factory, will enable a constant stream of information and feedback between HP and Shapeways. This work will be focused on making sure the quality, speed, and experience is second to none. (Seen here with Virginia Palacio from HP with Stefan Rink, our VP of Manufacturing)

In the early stages of testing, we will keep you posted on progress and hope to start using the machine to print your parts soon.

What’s so special about this new platform? Everything. Addressing 340 million 3D pixels or voxels per second, versus one point at a time means that the printer can bring high-quality nylon parts to life up to 10x faster than existing machines, at a much lower cost. This increase in speed could equate to the ability to move from same-week shipping to next day delivery. But that’s not all; Although this revolutionary system is rolling out with one color: Black nylon, over time the range of colors will dramatically increase, enabling the ability to include full-color plastic printing. Yes, full-color plastic, at a cost potentially lower than current dyed nylons.

Pete

Awesome! Absolute game changer! Go Shapeways & go HP!

Is there a order of magnitude time-frame guess for the availability of full color plastic??

How big can this print and how much per square inch does it cost?

Been waiting for this printer! 🙂

Black nylon is the equivalent of the current strong and flexible plastic material? Or will black nylon have different properties? Would like to start optimizing my products for this printer.

undetermined… but stay tuned for details 🙂

Good going Pete! 😀 I’m sure that will generate some excitement around here!!

When you can say, I’d like to know what the resolution is and how strong the material is? I’m wondering if it could be used to 3D print my Photographers Quadropod Case residing on my 3DPrintTheUniverse account. Feel free to grab that and use it in your experimentation if you’d like. S&F didn’t have high enough resolution and was not strong enough as well.

Looking forward to the future!!

What a fantastic piece of kit. Take a look at

http://h41367.www4.hp.com/campaigns/ga/3dprinting/4AA5-5472ENW.pdf

to see the potential.

I dread to even think how much it cost………….

So it begins!

Can’t wait to print on this machine one day and add more detail to even better coloured miniature Ittyblox buildings!

Can’t wait for full color plastic

(yes you can)

yeah I will

Faster cheaper OK you said it now let’s see it fingers crossed I like the direction shape ways is going

This is so very exciting. Well done SW and HP!

Very exciting news! This is indeed exactly what the market is waiting for. Fast delivery of 3d printed parts.

I am wondering… what will be the time frame for the next mile stone; full-color plastic?

We’re eager to let you know once we’re ready 🙂

Wow!! This is the best news!

I can’t wait for the R&D on this to pay off and we can do full colour, high quality printing!!

Seriously well done on this investment and partnership!

Plastic is no good, we can print that on own machines. We need large cheap metal printers.

Lower the price already. Let’s go!

Looking so out for the first pieces and finishing !

Will this allow larger prints?

potentially… this is just the start and a prototype to test in a true print-for-consumer setting.

Sounds awesome.

Another reason for me to hesitate buying my own 3D printing machine.

Any specs … e.g. minimum layer thickness, minimum wall thickness? Or are they the same as the current nylon material and the big leap is in speed and cost?

So great that Shapeways and HP are working together to bring 3D printing to the next level.

Congratulations to Pete and the whole Shapeways team!

Thank you for this wonderful update! I have been eagerly awaiting the introduction of the HP technology since I first read about it two years ago. Great going, Shapeways, for helping usher in a true revolution in custom manufacturing.

Can I Print figurines, and can I use Graphene too?

Not yet but that’s a great idea!

What Wallthickness can this machine print ?

What’s the max. Buildvolume ?

We’re still working closely with HP on this, more details will come as we get settled in with the machine

Great news!

Potentially a great step in the right direction.

I make products for model makers. Everyone loves the 3D print technology but cost and surface texture are major barriers to increased sales.

Can you tell me what the resolution is? also, minimun print thickness, length, etc..?

Thank you,

Frank

Just found the link to the HP site on this machine

It looks pretty impressive. there are a couple of good videos illustrating its potential

http://goo.gl/wQMQVR

Hopefully that takes you to the right place.

Thanks Tim. Very bizarre, I’ve emailed HP directly and heard back nothing.

That’s great news. When you say black nylon, can you share more about the mechanical properties such as flexibility, porosity, surface smoothness etc. I would like to optimize our wearable products for this printer. Thanks again!

Tick, tick, tick. Painful wait.

Impressive new machine! Can’t wait to order parts from it!

I was wondering, after watching the car lift video, are there any materials in Shapeways portfolio that can match the strength of the HP nylon print or is it significantly stronger than anything available currently?

Great to see a new option opening up.

A few important things not addressed.

When will we have access?

What will the cost be?

Will it have the same design rules as other ‘Nylon’ given the base material is the same/similar grain size distribution?

Any update on availability?

Holy moly, it’s like an info black out on this thing.

About the only thing I can squeeze out of anyone is that HP is expecting to announce their US machine in about a month. They said specs on US version may not be the same as EU version so they’re not releasing info.

That’s not to say HP machine will be in US’ Shapeways, just that HP is expecting US version will be available in about a month.

Wonderful article! That is the type of info that are supposed to be shared across the

web. Disgrace on Google for no longer positioning this post upper!

Come on over and talk over with my site . Thanks =)

It’s a great news to share with. Thanks for sharing this useful information with us.