3D printing and additive manufacturing are designations often used interchangeably. The terminology has grown more nuanced, however, as the original intent behind 3D printing in rapid prototyping has given way to manufacturing of high-performance, industrial parts. 3D printing, or additive manufacturing, has also expanded to unexpected proportions since its inception in the 1980s, evolving into a global industry expected to reach $76.17 billion by 2030.

3D printing is named for the ability to create a 3D product from a CAD file. The 3D printer deposits sequential layers of material onto a print bed, building the desired structure. Shapeways offers numerous technologies, with over 90 materials and finishes to choose from.

Additive manufacturing is a more descriptive term standing in contrast to subtractive manufacturing where materials are removed, resulting in the desired structure. While additive and traditional manufacturing offer advantages, Shapeways remains agnostic in terms of technology and materials, recommending the most suitable resources for excellence in product development.

So, is it additive manufacturing or 3D printing? Technically, the answer could be either as the processes are indeed the same. There is little denying, however, that the paths have diverged for these terms, exemplified at Shapeways at the Shapeways Marketplace, showcasing innovative 3D printed products globally, and another industrial division, promoting AM processes for manufacturers of all sizes.

3D Printing at the Shapeways Marketplace

Shapeways launched the Marketplace in 2008. Providing a business platform for thousands of designers, the Marketplace is open to shoppers and 3D print enthusiasts around the world. The choices are vast, with continued growth as shopowners continue to add 3D printed products.

Access to diverse 3D printing materials plays a large role in innovative success and product quality at the Shapeways Marketplace, whether designers are making vintage or miniature automotive parts or crafting fine jewelry to be cast in precious metal.

Shapeways offers Industrial Production for Manufacturers

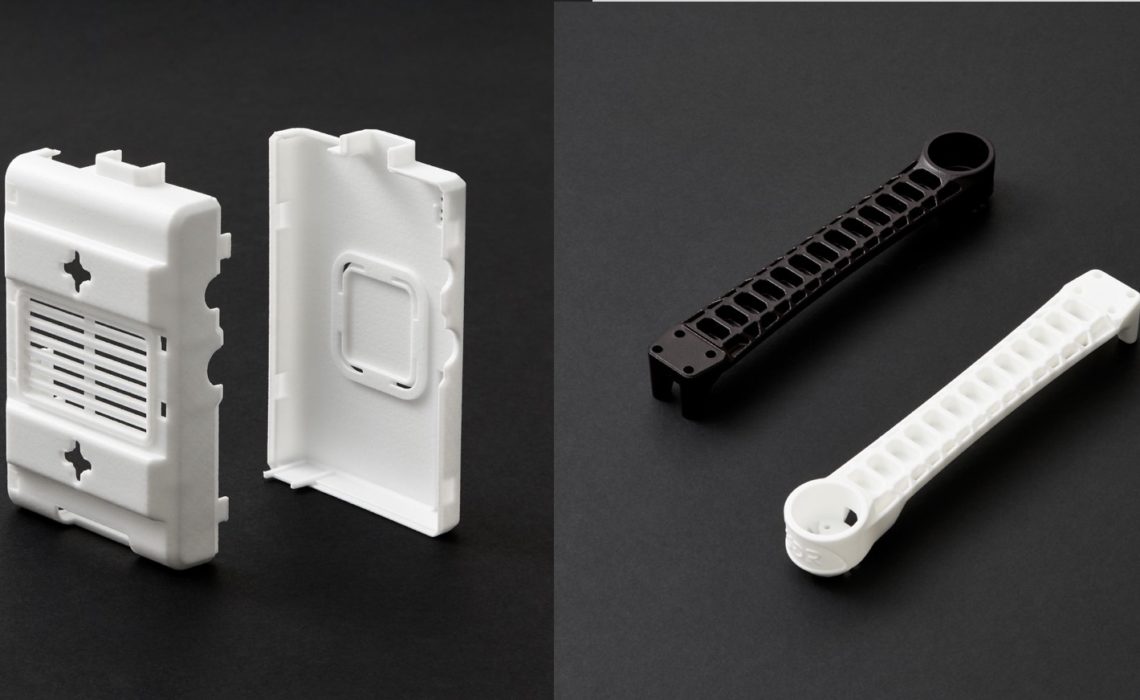

Additive manufacturing is typically associated with industrial production and large-volume runs. This is common with technology like Selective Laser Sintering (SLS), where Shapeways proprietary software for nesting orients 3D models, interlocking, rotating, sorting, and condensing them as tightly as possible for each build.

Shapeways customers may begin prototyping and testing products via 3D printing, moving forward to Injection Molding for mass production of parts. Others may go on to use additive manufacturing during product development and production of end-use parts. This is common in applications like the following:

- Aerospace – In drone technology, AM processes are relied on for comprehensive structural parts like drone frames, as well as smaller components like housings for electronics. Download the Quantum-Systems Case Study to find out how drone manufacturers can save thousands.

- Architecture – Designers are able to create detailed models in full color, as well as producing interior statement pieces on a large scale with reduced assembly. Download the Verner Architects Case Study to find out how an architectural firm created a 3D printed, six-foot-long vanity.

- Automotive – Digital fixtures demonstrate how AM processes figure into automotive production, allowing for rigorous testing of parts on any scale.

- Medical models and devices – Additive manufacturing is an excellent choice for products like full-color medical models, surgical training platforms, and devices like prosthetics and orthotics. Download the Armour Bionics Case Study to find out how important medical models can be in delicate surgeries.

- Robotics – The integration of additive manufacturing in robotics takes product development and functionality of high-performance parts to a new level, from customized robotic arms to devices capable of gripping and performing critical tasks.

Powder-Based Additive Manufacturing

Most 3D printing technologies begin with the same basics. A thin layer of powder is spread across the printing bed, to be melted one layer after another, building a structure. Technology includes Binder Jetting, Multi Jet Fusion, Selective Laser Sintering, and Selective Laser Melting.

Greater design freedom is available since supports are not required, and excess powder can be easily recycled, supporting sustainability in resources. Complex structures are possible, promising precision, and repeatability.

Resin-based 3D Printing

Resin-based 3D printing technology like Stereolithography (SLA) is a common choice for designers and engineers seeking intense detail and accuracy, often in intricate parts. They may also choose industrial processes like Material Jetting–another extremely accurate technology–but one that is very different from SLA. Known as one of the fastest methods of 3D printing, MJ technology relies on photopolymer resins to build layers until a part is complete.

Metal Additive Manufacturing

Metal AM processes continue to become more popular as industrial manufacturers seek complex geometries that are strong but lightweight. A wide range of technology is available for 3D printing metals, to include Binder Jetting and Selective Laser Melting. For applications like making 3D printed jewelry, many Shapeways customers rely on Lost Wax Casting. Offering the ability to make products with precious metals, Lost Wax Casting allows for production of luxury items like fine jewelry with complex shapes, interlocking parts, and even engravings.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.