-

-

- Manufacturing

- Industries

- Materials

-

ABOUT

Resources

- Get a Quote

-

My Shapeways

-

0

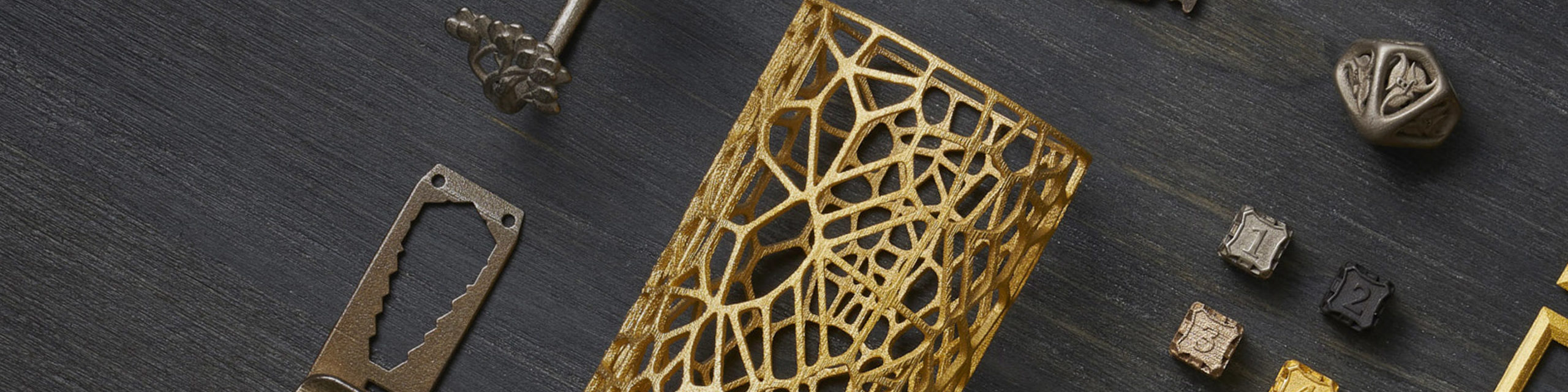

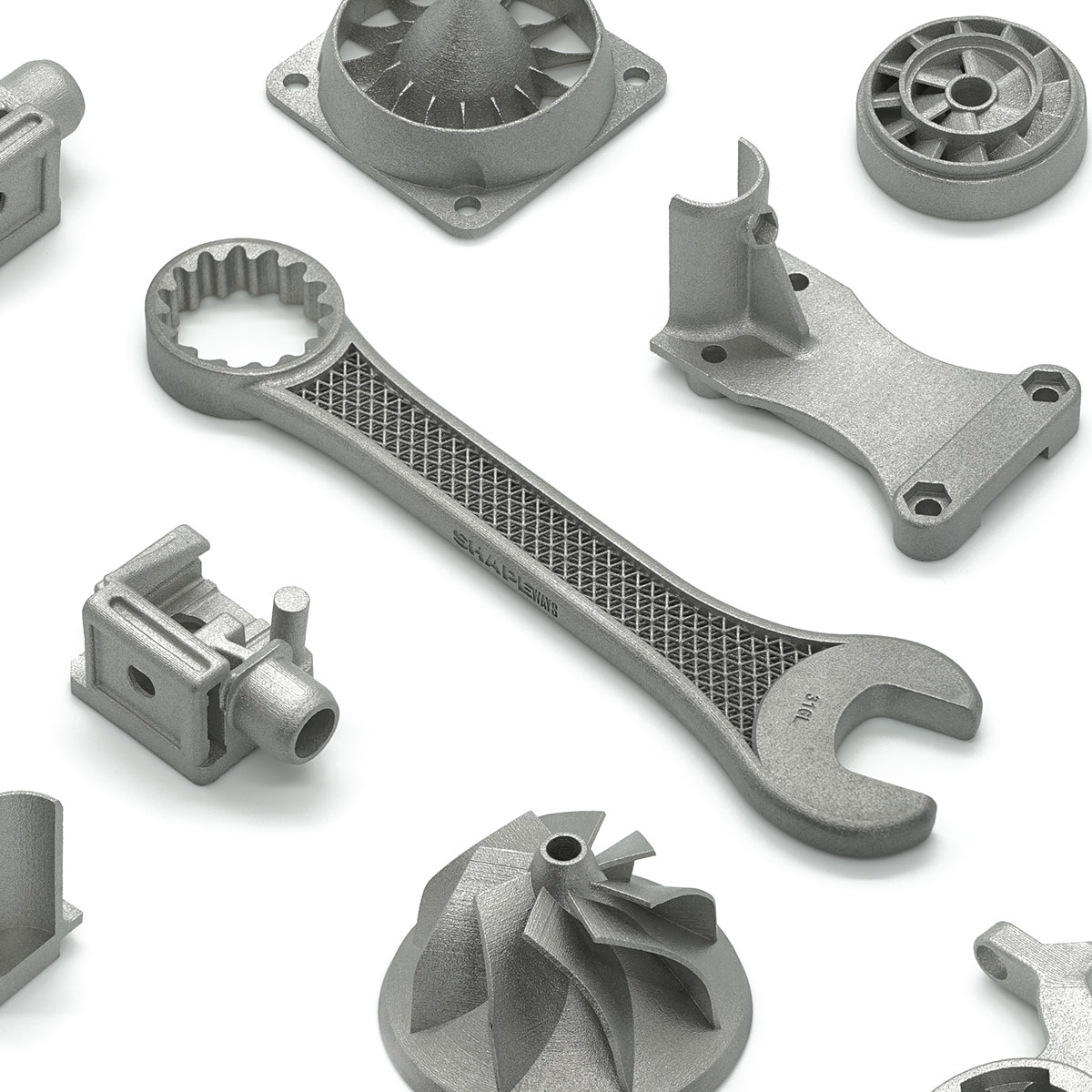

Steel is an affordable and strong metal that is well-suited for consumer products both small and large with an industrial look and feel. It’s printed using a binder jetting process and is later infused with bronze, creating a material that is 60% steel and 40% bronze and can range in color from a silver gray to reddish bronze. It is strong enough for metal parts like bottle openers and dice, but is not recommended for industrial load bearing applications. More information about this material can be found in our Help Center.

Bronze

Bronze

Bronzed-Silver

Bronzed-Silver

Black

Black

Maximum Bounding Box

762 × 393 × 393 mm (Bronzed-Silver, Bronze, Black)

152 × 152 × 76 mm (Polished)

178 × 178 × 178 mm (Plated)

Minimum Bounding Box

6 × 6 × 3 mm

The bounding box is a 3D imaginary outline of a box that encloses the smallest area occupied by your model. Your model must be within the minimum and maximum bounding box sizes. If the size of the model is close to the maximum bounding box, then the printing orientation will be restricted.

A supported wall is connected at least on two sides of the wall, while an unsupported wall is connected only on one side of the wall. Walls that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wall geometry of the model. Please consider the size of your model and reinforce the walls or add support structures as needed as minimum guidelines will not always be adequate for large models.

Model’s Longest Dimension:

3 to 75 mm = 1.0 mm

75 to 150 mm = 1.5 mm

150 to 200 mm = 2.0 mm

200 to 300 mm = 3.0 mm

Model’s Longest Dimension:

3 to 75 mm = 1.0 mm

75 to 150 mm = 1.5 mm

150 to 200 mm = 2.0 mm

200 to 300 mm = 3.0 mm

A wire is a circular, rectangular or even triangular feature that is thinner in its unconnected directions than its length. A supported wire is connected at least on two sides of the model, while an unsupported wire is connected on one side of the model. Wires that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wire geometry of the model. Please consider the size of your model and reinforce the wires or add support structures as needed as minimum guidelines will not always be adequate for large models.

1.0 mm high & wide

1.0 mm high & wide

For text, the ratio between width and depth, should be 1:1 and sans-serif fonts are preferred for line weight consistency.

4.0 mm

2.0 mm

Escape holes are necessary to empty the support material of a hollow model. Two escape holes at the opposite ends of the model is optimal for the support removal process. Please consider the size of your model and make the escape holes bigger or add more escape holes as needed as minimum guidelines will not always be adequate for large models.

3.0 mm

Clearance is the space between two individual parts in a model. If the space among the individual parts do not meet the minimum clearance, then parts can fuse together or can be difficult to clean. This is important for movable pieces like hinges, gears, etc.

Interlocking

No

Enclosed

No

Up to 250

±5% The bronze infiltration of each steel part makes this material less dimensionally accurate than other Shapeways materials. Shrinkage is more prevalent, especially on small holes and inner diameters. Accuracy and tolerance can vary greatly depending on the model, and are hard to predict because they are so geometry specific. A 5% deviation on a ring is around 1 US ring size. So if you order a size 6, the deviation could cause the actual print to be a size 5 or 7.

"*" indicates required fields

From product development to industrial 3D manufacturing, we can help you scale your business.

contact sales