Read on to find out more about:

- Why Nylon 12 [Versatile Plastic] continues to rise in popularity for 3D printing across a wide range of industries.

- How the Premium finish adds an upscale touch to 3D printed products.

- Comparisons between the Premium finish and the Natural Finish in terms of material properties, detail, painting, and more.

Shapeways offers over 90 different materials and finishes, with Nylon 12 [Versatile Plastic] topping the list in popularity. 3D printed with Selective Laser Sintering (SLS) technology, this material is an industry favorite–and a well-named one–in terms of incredible versatility.

Flexible for thinner structures and strong for thicker ones, Nylon 12 [Versatile Plastic] offers excellence in mechanical properties, including tensile strength, durability for long-term use, and resistance to abrasion, fatigue, and stress.

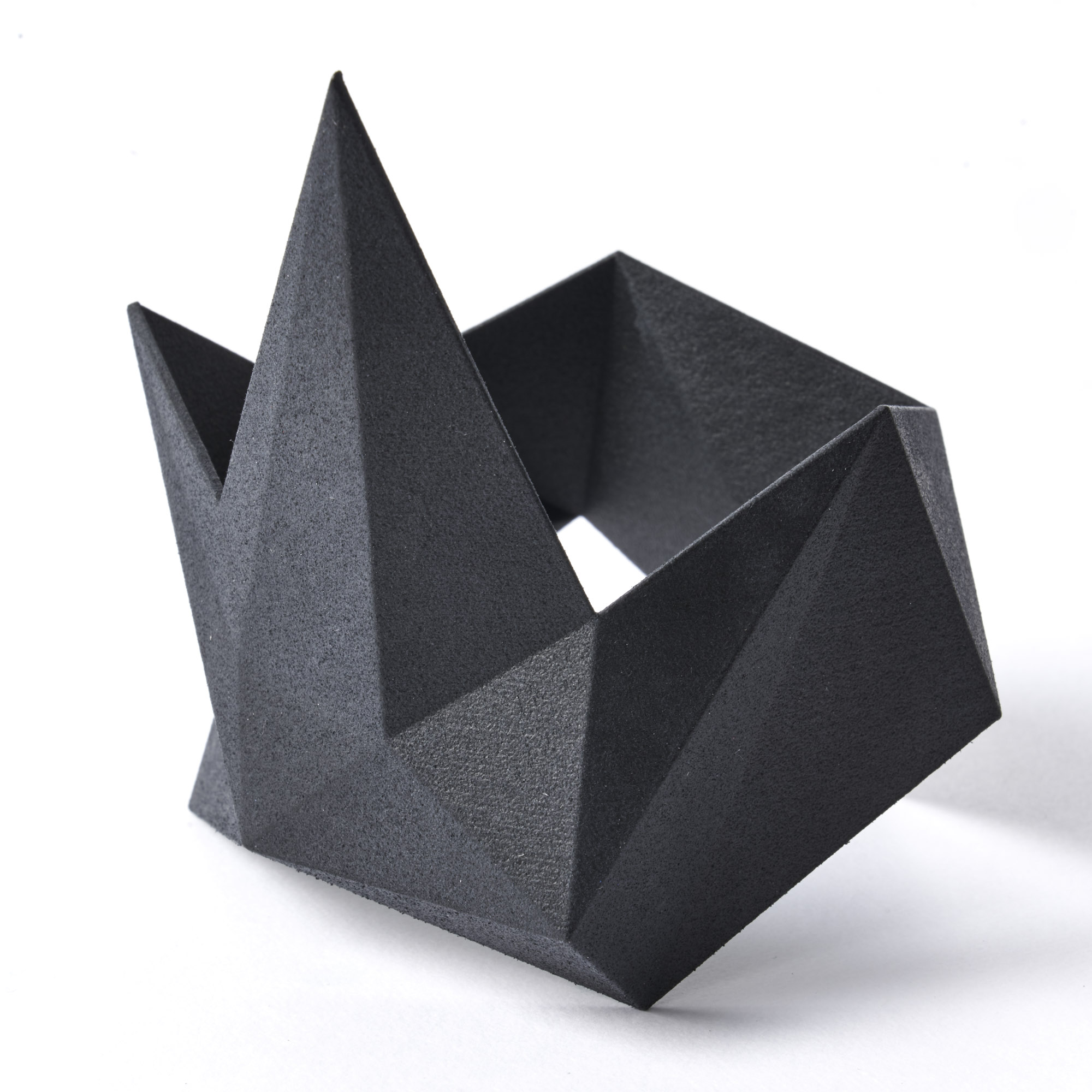

Premium Nylon 12 [Versatile Plastic] offers an upscale finish, elevating designs with a smoother and glossier surface, offering a surface texture that is soft to touch. The Premium finish is recommended for the following:

- Interlocking parts

- Fine jewelry

- Home decor and art pieces

- Accessories like phone cases

Shapeways employs a multi-step tumbling, polishing, and dyeing process to create a consistent color and surface finish, while removing the grainy feel and layered look of 3D printed parts. Customers continue to rely on Nylon 12 [Versatile Plastic] and finishes like Premium for some impressive projects, on the small and large scale:

Verner Architects designed a six-foot vanity for a luxury remodel on a home in California. Shapeways 3D printed their interior statement piece with durability and water resistance in mind since it was for a childrens’ bathroom. Other manufacturers like Tilt Hydrometer collaborated with Shapeways to 3D print free-floating monitoring devices for homebrewing, while 67 Designs has installed 3D printed luxury accessories like iPad mounts in their off-roading vehicles.

Over time, there have been many questions about the Premium finish, answered in the FAQs section below:

Material Properties

Are the material properties the same between regular Nylon 12 [Versatile Plastic] and Premium?

Yes. The same 3D printing material and SLS technology is used for Premium.

Appearance

But exactly how is it different then? Are there images of samples available?

Premium finish was created to enhance 3D printed products with a more finished look that equals the aesthetics of injection-molded products. The smoothness and eggshell sheen of Premium should meet the demands of high-end consumers too, lending a more professional appearance for unique, customized products.

Feel and Surface Roughness

How much smoother is Premium?

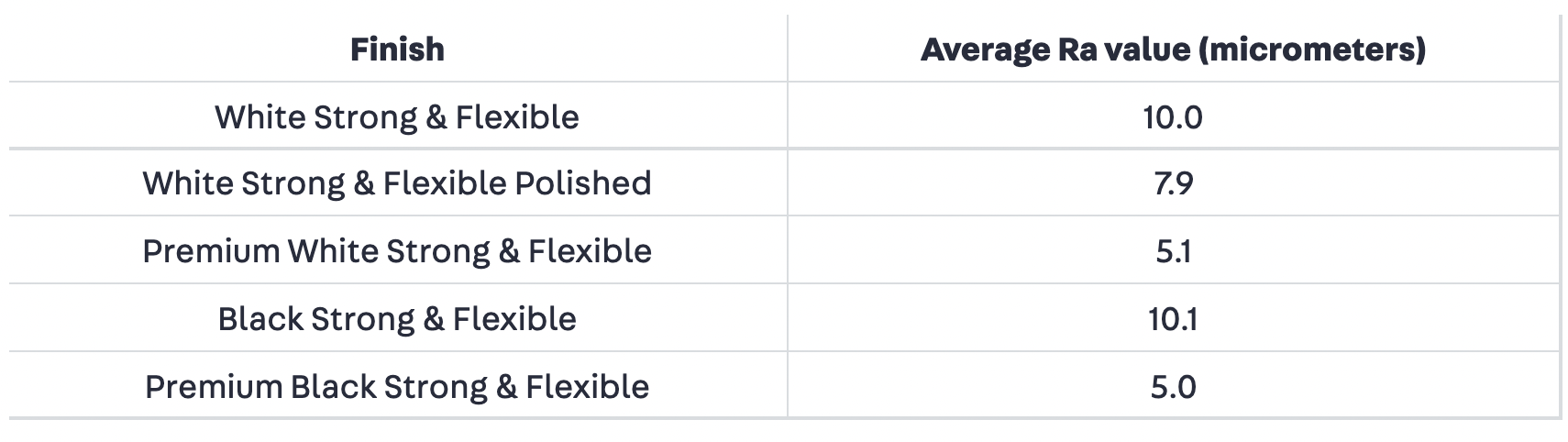

Just saying Premium is smoother can be too vague, so Shapeways performed surface roughness tests. A surface roughness tester quantifies the texture of a surface by measuring the distance between the peaks and valleys. The larger the distance and the higher the value, the rougher the surface is. Small values indicate a smoother surface.

Surface roughness is measured by its Ra value. Ra is the average of these distances between the peaks and values on the surface to its ‘mean line.’ You can think of the mean line as the center line between the peaks and values.

Looking at the values in the table above, the Ra of Premium measured around 5 micrometers whereas regular Nylon 12 [Versatile Plastic] measured around 10 micrometers. This means that Premium is about twice as smooth.

Dimensional Accuracy

Is dimensional accuracy different with the Premium finish?

Shapeways also tested the effect of Premium finishing on the dimensional accuracy of parts by measuring multiple dimensions both before and after post-processing. Six measurements were taken on six different parts. On average, the parts decreased in size by 0.9mm. The maximum material removed was 0.1mm.

Scaling up your design slightly to account for this difference is recommended if dimensional accuracy is important for your product’s application.

Detail Level

Do you lose intricacy in detail with Premium?

Although the dimensional accuracy changes slightly with Premium, no visible difference in details are found. Both embossed and engraved details looked very similar before and after finishing during testing.

About Shapeways

Contact Shapeways now to enjoy the benefits of advanced technology and materials for manufacturing creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to make over 21 million parts! Read about case studies, find out more about Shapeways solutions, and get instant quotes here.