3D printing is spreading far and wide and is being used by hobbyists, students, academicians, engineers, and industry professionals. The technology has heralded the new age of manufacturing. One of the keys to its success? Design thinking.

What is Design Thinking?

Design thinking is an approach to new product development, strategy development and for ‘truly’ meeting customers’ needs. It’s used to provide a framework which helps engineers, designers, and new product development teams to identify a problem or opportunity and to find appropriate solutions to those pressing problems.

Design thinking is defined by three steps:

Empathy

Empathy, or human centeredness, is the first step in the design thinking process. It literally means empathizing with the customers to understand their desired and unmet needs and to identify what they really want from the solution to their problem. This step focusses on keeping the human at the center of the problem-solving sphere. Only by focusing all the efforts on identifying the core needs of the customer will the product be designed to their needs.

Ideation

The second step is to ideate. To generate a stream of ideas to solve those identified needs. It is impossible to incorporate the needs of the customer in a single or a couple of ideas, so the objective is to generate a wider range of ideas.

Experimentation

The last step of the design thinking process is important from a product manufacturing point of view. This step encourages the engineers to experiment with the ideas created in the earlier step. Experimentation is extremely important for understanding the customer’s reactions and feedback on the generated ideas.

Four Important Considerations of Design Thinking

Graphic by Abhimanyu Chavan

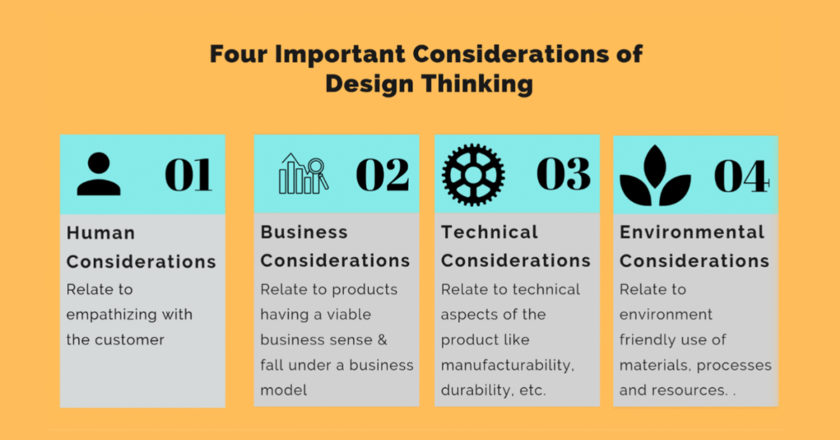

A more profound approach to design thinking makes four important considerations: human considerations, business considerations, technical considerations, & environmental considerations.

Human Considerations

These considerations directly relate to empathizing with the customer to understand their needs.

Business Considerations

Apart from understanding needs and generating a lot of ideas, it’s also important to understand the business considerations. The products should fall under a business model and it should have a viable business sense in manufacturing and selling those products.

The products should give a return on investment and has to generate sufficient profits. Special care should be taken to avoid an instance where all ideas are converted into products.

Technical Considerations

This relates to the technicality of the product: manufacturability, durability, economics and other such technicalities that can hamper the product and indirectly the brand which sells it.

Environmental Considerations

As people are becoming more aware of the environment and constantly demand sustainable products, it becomes critical to think of the environmental impact of the product as well. This relates to the considerations regarding environment-friendly materials, processes, and resource saving.

Why design thinking is the key to 3D Printing success?

For a long time, engineers have been creating products through the traditional manufacturing process by designing products in a certain way. But now with the advent of 3D printing, the designing and manufacturing rules have changed. We now have to evolve the designing process in order to manufacture products in a new way, making design thinking important to 3D printing.

By implementing the design thinking approach, manufacturers can take advantage of the capabilities of 3D printing to create products that revolve around the customer’s needs.

3D printing is a technology that has the capability to rapidly iterate, as 3D models can be rapidly manufactured using a 3D printer. The prototype can then be tested for any functional or design discrepancies. If any, the model can be modified and again 3D printed as rapidly as the first time and again tested for any errors.

The multitude of ideas generated in the ideation phase of design thinking can be rapidly manufactured and experimented with to shortlist the best products which will be introduced in the market.

As much as 3D printing is important for the sustenance of the design thinking approach, design thinking is also equally, if not more, important for the success of 3D printing.

Design Thinking and 3D Printing at Crossroads

For a long time design thinking approach has been relegated to the books and mostly seen as a theoretical approach when in fact it is more than relevant in today’s world where the products are manufactured and push-marketed to customers to satisfy their undesired needs. The core solutions are still far from reality.

On the other hand, we are witnessing a manufacturing revolution pioneered by 3D printing. 3D printing is a revolutionary technology that has given designers unprecedented freedom to design complex products. It has helped engineers to manufacture complex parts that were previously impossible to produce. It has sped up the time-to-market by cutting down the tooling time. This has also resulted in immense cost-savings to manufacture those tools to start with.

And so, it’s time to think critically and ponder how the world will move forward. Today, 3D printing and design thinking are at crossroads where they should be studied and applied together to achieve innovative and customized results.

Applying design thinking principles for new product development can lead to a better understanding of the advantages of 3D printing technology and how it is a boon for manufacturers from all sectors. By designing products without any constraints and manufacturing them rapidly, there is a common acceptance that design thinking is the key to the success of 3D printing and both these together can prove to be the driving force behind the current manufacturing revolution.